|

Altrasonic Equipment(shanghai)co.,ltd

|

20Khz High Intensity Ultrasonic Homogenizer Equipment For Crude Oil Pesulfurization

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

20Khz High Intensity Ultrasonic Homogenizer Equipment For Crude Oil Pesulfurization

Spec

20Khz High Intensity Ultrasonic Homogenizer Equipment For Crude Oil Pesulfurization

Specifications:

|

Model |

S20-500 |

S20-1000 |

S20-1500 |

S20-2000 |

S20-3000 |

|

Frequency |

20±1 KHz |

20±1 KHz |

20±1 KHz |

20±1 KHz |

20±1 KHz |

|

Power |

500 W |

1000 W |

1500 W |

2000 W |

3000 W |

|

Voltage |

220±10% V |

220±10% V |

220±10% V |

220±10% V |

220±10% V |

|

Temperature |

300 |

300 |

300 |

300 |

300 |

|

Pressure |

35 MPa |

35 MPa |

35 MPa |

35 MPa |

35 MPa |

|

Intensity of sound |

10 W/cm² |

20 W/cm² |

30 W/cm² |

40 W/cm² |

60 W/cm² |

|

Max Capacity |

5 L/Min |

10 L/Min |

15 L/Min |

20 L/Min |

30 L/Min |

|

Material Of Tip Head |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

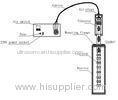

Principle:

Ultrasound-assisted oxidative desulfurization is a very attractive alternative to the traditional hydrodesulfurization technology.

Exposing liquids to high-intensity ultrasound greatly promotes mass transfer-limited reactions and surface chemistry of catalysts. Ultrasound creates acoustic cavitation, which produces violently imploding vacuum bubbles, causing shock waves, micro-jets and strong shear forces as well as extreme local temperatures (~5,000 K) and pressures (~1,000 atm). These extreme conditions result in exceptionally efficient mixing, yielding nanoemulsions with very small droplet sizes and enormous contact areas between all components. The oxidative desulfurization of crude oil is, therefore, considerably accelerated by exposure to high-intensity ultrasound.

Main Functions:

This method may be a sulfur content of thousands g / g diesel reduced to l5 g / g.

Experimental results show that the reaction from DBT to DBTO (dibenzothiophene oxide) need only 1 min and 3 min, the conversion rate can reach 85% and 95%, respectively, 7 min can all oxidation.

Experimental results show that the reaction from DBT to DBTO (dibenzothiophene oxide) need only 1 min and 3 min, the conversion rate can reach 85% and 95%, respectively, 7 min can all oxidation.

While no ultrasound from DBT to DBTO conversion rate was 2l%, 7 min reached only 80 percent, significantly lower than the conversion rate of 1 min ultrasonic treatment.

This fully shows that the role of ultrasound in oxidative desulfurization.

Competitive Advantage:

- Custom System Designs and Consulting,

- Active Ultrasonics provides consulting services and custom reactor designs,

- High amplitude probe,

- Unrestricted flow-through cylindrical systems,

- High Power Probe Sonicator.

Other Applications:

- Disruption of cells, bacteria and tissues,

- Adjustment of ribosome,

- Cutting of actinomycetes and fungal threads,

- Acceleration of a chemical reaction,

- Extraction of special components by disruption of tissue fragments,

- Emulsification and dispersion in samples (a mixture of liquids such as water-oil, water-silver, etc.).

WHY CHOOSE ALTRASONIC ?

- OVERSEA SERVICE TEAM. We now have agents in India, Austrilia, Hongkong, Singapore, Taiwan, Malaysia, Germany, and other country still being discussing.

- Innovation. Altrasonic R&D and marketing staffs to constantly explore new applications in the field of ultrasound, and the importance of team spirit of cooperation.

- Half the price, double the value. Every product reach you have been test in our company three times, and with 72 hours continous working, to confirm it is well before you get it. Also we always learn from foreign company, to upgrade our products.

- Good components. Ceramic mainly imported from German, and using the superior quality aluminum, titanium raw materials.

- Individual Customize. We can customize products according to your requirements, Also supply OEM service. Customize ultrasonic solution for different applications.

20kHz High intensity ultrasonic equipment for crude oil pesulfurization , with large amplitude

Related Search

High Intensity Flashlight

Crude Oil

Homogenizer

Crude Palm Oil

Crude Oil Pipe

Crude Sunflower Oil

More>>