|

Altrasonic Equipment(shanghai)co.,ltd

|

Gold Index: 7193

Electric Ultrasonic Bonding Machine 2600 Watt For Nonwovens Films / Textiles

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Electric Ultrasonic Bonding Machine 2600 Watt For Nonwovens Films / Textiles

<

Electric Ultrasonic Bonding Machine 2600 Watt For Nonwovens Films / Textiles

Description:

With ultrasonic sealing, the heat required for melting is only generated inside the thermoplastic sealing layer. For localized conversion of vibrations to friction heat, the anvil or sonotrode profiles are mostly linear. These profiles ensure focusing of the energy input and therefore short sealing times between 100 and 200 milliseconds. With ultrasonic sealing heat is generated at the inside of the film, not by heat input from the outside as is the case with heat sealing, for example. The tools (sonotrode and anvil) that come into direct contact with the packaging material, remain cold during the entire weld process. The support layer remains almost cold and upon termination of energy input, the heat dissipates faster to the outside due to the temperature difference between the support layer and the sealing layer so that the hot-tack resistance is significantly higher.

|

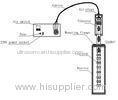

Components |

ultrasonic transducer and ultrasonic generator |

|

Frequency |

15 khz |

|

Power |

2600w |

|

Application |

Non-woven bag making machine |

|

Operation mode |

Automation |

|

Materials of horn |

Steel or titanium optional |

|

Type of horn |

Depending on customer's requirements |

| Voltage | 380V / 220V |

Application:

Apply to lace clothing, ribbon,trim,Filter, Lacing and quilting,decoration products, handkerchief, tablecloth, curtain, bedspread, pillowcase, quilt cover, tent, raincoat, disposable operating coat and hat, disposable mask, non-woven fabric bags and so on.

Principle:

Ultrasonic lace sewing machine used ultrasonic vibration and steel moulds, the above processing will be finished together with pressure.

Function:

Raw material - Bag mouth fold - thermal bonding - side fold - bottom sealing - loop handle fix - thermal bonding - edge cut - bag cut - collection

Advantages:

1. There’s no fog and spark in produce processing, won’t cause damage to fabric edge,

and also can avoid deckle edge.

2. Chang of the ultrasonic cutting die is very easy, and the design of themoulds can

also made according to customer’s requirement.

3. Without pre-heating, and continuous operation is possible.

4. Machines can be combined to one set of equipments in order to sew large width

products once, for instance, guilt cover, gingham, etc.

5. The cutting moulds (cutting die) that be made of special alloy steel which has been

treated with special heat treatment technology, so the moulds with high wear resistance

and gains a longer service life.

15khz 2600watt high power ultrasonic bonding of nonwovens films and textiles , bag making machine

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Altrasonic Equipment(shanghai)co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Hangzhou

Province/State: Zhejiang

Country/Region: China (Mainland)