|

Altrasonic Equipment(shanghai)co.,ltd

|

Gold Index: 7193

Automotive Ultrasonic Food Cutting Machinery For Sausage Pork Beef Cutting

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Automotive Ultrasonic Food Cutting Machinery For Sausage Pork Beef Cutting

<span style="font-family:arial

Automotive Ultrasonic Food Cutting Machinery For Sausage Pork Beef Cutting

Description:

The ultrasonic food cutting machine (cutter) is composed of ultrasonic transducer (converter) with cover, booster, titanium blade and digital generator.

Ultrasonic cutters can smoothly cut difficult-to-cut materials.

They are small in size and do not require large installation areas. Special equipment is not required for the installation. They are small enough to be hand-held for many operations. They can also be attached to automated machinery arms. Although they may not be familiar to you, they play an active role in the manufacturing processes of various industrial products which we use daily.

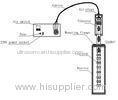

The ultrasonic cutter is composed of a “transducer” that generates vibration and an “oscillator” that drives the transducer. A piezoelectric element is used for the transducer. When voltage is applied, the piezoelectric element displaces the transducer by a few micrometers. Periodically applying voltage generates vibration. Each object has its special frequency, by which the object is stable and easy to vibrate. By adding an external force that corresponds to that special frequency, a small force can obtain a large vibration. This phenomenon is called resonance.

In the ultrasonic cutter, the piezoelectric element generates a force that resonates the whole body, from the transducer to the blade tip, generating a large vibration at the tip. The oscillator periodically generates voltage to resonate and drive the transducer. Using a component of the ultrasonic cutter called the horn to wring the cross-sectional area, from the piezoelectric element to the blade tip, can obtain a larger vibration.

Ultrasonic cutting advantage and features:

1. Cut the material quickly and precisely

2. Smooth and traceless cutting edge

3. Powerful, effective realiable

4. Low cost, easy operator. An operator only handle the probe and step the foot switch .So anybody can use it easily.

|

FREQUENCY |

20Khz |

|

POWER |

800W |

|

INPUT |

AC110-240V, 50/60Hz |

|

POWER CONTROLLER |

stepping or continuous |

|

MATERIAL OF CUTTING HEAD |

, stainless steel, titanium alloy, alloy steel. |

|

MACHINE WIGHT |

15~18KG |

|

ACCESSORIES |

foot switch, additional blade |

|

COOLING DEVICE |

compressed air mouth can be installed. |

|

CABLE LENGTH |

3M or customized |

|

FOOT SWITCH |

available |

Applications:

1. For thermal plastic gate cutting and flush cutting.

2. For non-woven or woven cutting,textile cutting, fabric cutter, curtain cutting,window blind fabric

3. For rubber, PVC, leather plastic, cardboard, acrylic, polyprolene and so on cutting.

4. For tape and film cutting .

5. For paper cutting,printing industry cutting.

6. For package material cutting

7. For the automotive industry cutting

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Altrasonic Equipment(shanghai)co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Hangzhou

Province/State: Zhejiang

Country/Region: China (Mainland)