|

Altrasonic Equipment(shanghai)co.,ltd

|

Electronic Ultrasonic Cutting Machine For Textiles Fabrics / Plastic Sheets

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Electronic Ultrasonic Cutting Machine For Textiles Fabrics / Plastic Sheets

Specifications

Electronic Ultrasonic Cutting Machine For Textiles Fabrics / Plastic Sheets

Specifications:

|

Model |

HS-C40 |

|

Frequency |

40KHZ |

|

Output Power |

100W |

|

Generator |

Analog generator, 155 x 265 x 170mm |

|

Handle |

Φ32×170 |

|

Size of cutter |

Blade replaceable |

|

Length of cable |

3M |

|

Outer skin |

Aluminum |

|

Weight |

8KG |

|

Voltage |

220V / 110V |

|

Accessory |

Foot switch1pc |

|

Material of cutter |

Magnalium alloy, titanium alloy, stainless steel |

Description:

Ultrasonic Cutting Machine is a class of device using ultrasonic energy for cutting. Instead of using traditional blade cutting, ultrasonic cutting has its advantages of smooth, reliable cutting, accurate trimming, no deformation, no raising, fuzzing, spinning, wrinkling etc. It can avoid the rough cutting-edge, coked edge, fuzzballs and other shortcomings of laser cutting machine.

Ultrasonic cutting machine is used for cutting rubber, synthetic fabric, cloth, plastic, sheet metal, food etc.

The cutting of food products using ultrasound is performed when an ultrasonic blade comes into contact with the product to be cut, the high vibration of 40,000 pulses per second, makes this product very easily be cut even if it is of delicate or sticky texture composition. The much higher vibration does not allow any product to stick to the blade. The cut is clean and without pressure on the product.

Applications:

Natural fibers

Synthetic fiber

Thin plastic products(Such as plastic film, cell phone case)

All types of paper, bottom film

Rubber, silicone

Repair of printed circuit board copper foil

ABS,PP,PE … other organic plastic sheet less than 2mm

Various types of synthetic fabrics

Competitive Advantage:

The use of high power ultrasonic transducer vibrating element, ensure the long time stable working

The cutting speed is improved greatly, the efficiency 10 times higher than the traditional cutting knife.

Cutting all kinds of ordinary tool to cut products, solve production problems

Can be installed high hardness blade, cutting blade can be replaced, greatly reducing the use cost

Cutting tool complete varieties, can also be customized according to customer process shaped cutting tool

Installation, easy to use, almost does not change the original cutting process

Can be used in the production of circular ultrasonic tool cutting equipment, rolling cutting, suitable for cutting special

Can use air-cooled, water-cooled design, adapt to various working conditions and environment

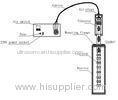

Problem and solution

|

Item |

Problem |

Cause description |

Solution |

|

|

Power switch to “I” the light is out |

Power plug loose |

Plugging in |

|

Power line break |

Fix it yourself or send back |

||

|

Power switch bad contact |

|||

|

Fuse is broken |

|||

|

Power light and running light are OK |

Air plug and socket not connected |

Tighten the connection position |

|

|

Handle have abnormal Sound |

Clean the card slot, use new blade |

||

|

Intermittently use, but the handle keeping hot |

Please send it back |

||

|

Out-put air plug break |

|||

|

Screw loose |

Tighten the screw |

||

|

Running light is ok |

Running switch bad |

Please send it back |

<