|

Altrasonic Equipment(shanghai)co.,ltd

|

Gold Index: 7193

60 Khz High Speed Ultrasonic Plastic Welder For Rfid Inlays / E Identification

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

60 Khz High Speed Ultrasonic Plastic Welder For Rfid Inlays / E Identification

Des

60 Khz High Speed Ultrasonic Plastic Welder For Rfid Inlays / E Identification

Description:

Ultrasonic smart card welding equipment transmitted ultrasonic energy through welding parts to welding area, local high temperature will happen due to high acoustic resistance between two welding interface places. Also, no enough time dissipating out heating energy timely because of poor plastic thermal conductivity, heating energy gathered in welding area since could not dissipating out timely, the two plastic contact areas will welt rapidly, coupled with a certain pressure, it makes fusion to one unite. When ultrasonic stop function, and keep the pressure sustain to make its solidification molding, finally forming a strong molecular chain, which achieve the purpose of welding. And the welding strength can close to raw material body strength.

Specifications:

|

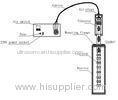

Components and Parts |

Ultrasonic digital generator |

|

Booster |

|

|

Converter |

|

|

Embedding / welding horn |

|

|

Protective Sleeve (Nylon and Aluminum optional) |

|

|

HF Cable |

|

|

Power cord |

Principle:

High Speed wire embedding with multiple embedding heads. Using the latest in linear servo technology and ultrasonic embedding units coupled together with vision cameras the wire embedding system is unrivalled in its speed, accuracy and the quality of antennae that it produces. Capable of working with a range of materials and wire diameters and an easy to use interface making solid wire antennas was never so easy.

Applications:

provide a range of flexible and efficient machine solutions for processing RFID inlays used in the secure eID (ePassports, eID cards, eHealth cards) & ePayment sectors as well as the contactless card markets.

Main advantages:

1. Steady welding point, completely eradicate insufficient solder technically.

2. The size of welding spots is the same, equality line, good effect on uniformity

3. The welding spot is small, wouldn’t increase the weight of the coil, easy to do lamination and encapsulation

4. To leave out the immersion tin step before doing welding ,save an operator.

5. After skilled in welding, much faster than the way to use searing iron to do weld.

6. On the process on manufactory,there is no waste gas, waste rubbish on pollution, runs in quiet and no noise.

7. To select the the frequency 60KHz, one machine could drive 5-10 ultrasonic products, the speed to do welding is much faster.

8. Low power consumption, to save production cost for manufactory enterprise.

high speed 60 khz ultrasonic parts for processing RFID inlays , smart card & E - Identification solutions

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Altrasonic Equipment(shanghai)co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Hangzhou

Province/State: Zhejiang

Country/Region: China (Mainland)