|

Altrasonic Equipment(shanghai)co.,ltd

|

Time / Welding Depth Setting UltrasoundPower Supply Real Time Distributed Control

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Time / Welding Depth Setting Ultrasound Power Supply Real Time Distributed Control <span style="

Time / Welding Depth Setting Ultrasound Power Supply Real Time Distributed Control

Description:

The principle of ultrasonic welding by the ultrasonic digital generator 50/60 Hz current is converted into 15,20,30 or 40 kHz energy, even reach 60khz. The high frequency electrical energy is converted by the transducer is again converted into a mechanical movement of the same frequency, followed by the mechanical motion transmitted to the weld head through a set can change the amplitude modulator means. The welding head will be received by the vibration energy transmitted to the engaging portion of the workpiece to be welded, in the region, the vibration energy is by friction by conversion into heat, the plastic melts. Ultrasonic can not only be used to weld the hard thermoplastic fabrics and films can also be processed.

Applications:

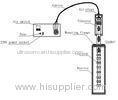

Ultrasonic generator main function is to generate high power and high frequency alternating current, drive the ultrasonic transducer.

Ultrasonic generator is applied to all kinds of ultrasonic equipment, mainly with ultrasonic welding, ultrasonic cutting, ultrasonic chemical equipment and ultrasonic welding equipment such as non-woven fabric.

Specifications:

|

Competitive Advantage:

1. High stability: All-digital integrated circuits, use of US imports of processors interference, simplify the hardware structure, improving the reliability of the system.

2. Automatic frequency tracking.

3. Strong output: The use of IGBT power modules plus his excited oscillation circuit structure, the output power is more than 1.5 times that of conventional self-excited circuit.

4. Amplitude stepless adjustment: Amplitude setting range from 10% to 100%.

5. Intelligent three protection and fault alarm: Die-current protection, frequency offset protection, total output is too large to protect. Equipment failure, the generator will stop working, and make the appropriate cause of function prompts until technician troubleshooting.

6. Intelligent closed-loop amplitude control technology to achieve the amplitude adjustment, independent of input supply voltage and load fluctuations affect the amplitude of the output remains constant.

7. Two kinds of welding mode: switch back and forth, so that a higher precision welding, soldering and better results.

Comparison:

| Analog generator | Digital generator |

Circuit | Analog circuit, discrete components | Digital circuit, the chip control |

Automatic search | × | |

Automatic frequency tracking | × | |

Frequency adjustment range | ±0.15 KHz | ±0.5 KHz |

Power regulation | × | |

24 hours of continuous work | × | |

Non resonant condition | × | |

LCD | × | |

Add the PLC protocol | × | |

Automatic circuit protection | Bad, easy to cause the damage of components | Good |

Repair method | Professional repair | Module replacement |

WHY CHOOSE ALTRASONIC ?

1. OVERSEA SERVICE TEAM. We now have agents in India, Austrilia, Hongkong, Singapore, Taiwan, Malaysia, Germany, and other country still being discussing.

2. Innovation. Altrasonic R&D and marketing staffs to constantly explore new applications in the field of ultrasound, and the importance of team spirit of cooperation.

3. Half the price, double the value. Every product reach you have been test in our company three times, and with 72 hours continous working, to confirm it is well before you get it. Also we always learn from foreign company, to upgrade our products.

4. Good components. Ceramic mainly imported from German, and using the superior quality aluminum, titanium raw materials.

5. Individual Customize. We can customize products according to your requirements, Also supply OEM service. Customize ultrasonic solution for different applications.